DTF Cotton Printing is a modern technique for custom fabric design using specialized paper, heat, and pressure to transfer ink directly onto cotton fabrics. It offers speed, cost-effectiveness, and superior print quality, making it popular for t-shirt printing and other garments. Key steps include digital design preparation, cutting DTF paper, transferring the design via heat and pressure, and ensuring precise registration and drying processes. This eco-friendly method bypasses traditional screen printing, using custom sheets, DTF printers, and non-toxic cotton inks for versatile, high-quality results sought by fashion designers and small businesses.

Avoid common pitfalls in Direct to Fabric (DTF) cotton printing with our comprehensive guide. DTF printing offers vibrant, durable results directly on cotton fabrics, but understanding its nuances is key. This article dives into the basics of DTF cotton printing, exploring critical errors like inaccurate design prep and suboptimal parameters. We provide effective strategies to ensure success, covering best practices for design setup, fabric preparation, and machine calibration. Master these techniques to elevate your DTF printing outcomes.

- Understanding DTF Cotton Printing: Basics and Process

- – Brief explanation of Direct to Fabric (DTF) cotton printing

- – Key components and materials involved

Understanding DTF Cotton Printing: Basics and Process

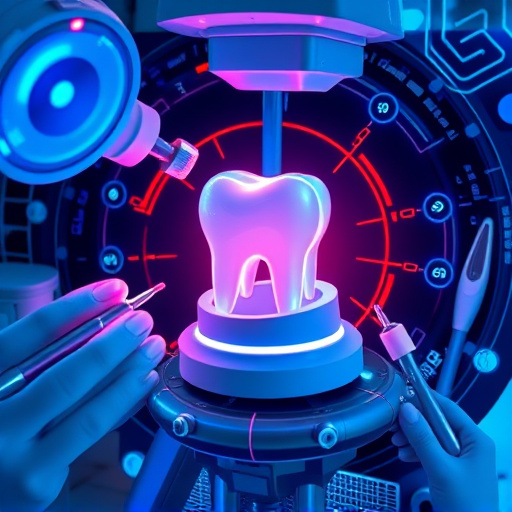

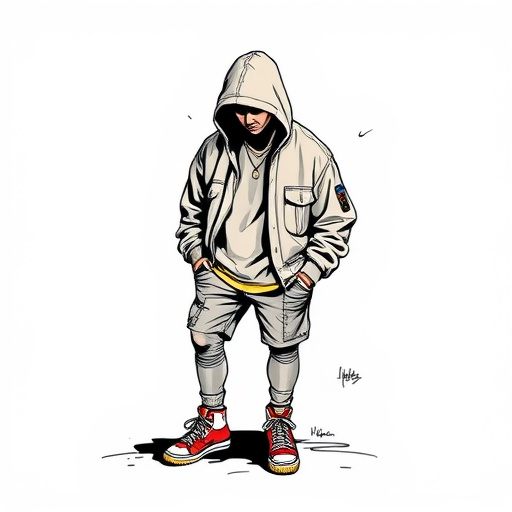

DTF Cotton Printing, or Direct-to-Fabric Transfer, is a popular method for creating custom designs on cotton materials like t-shirts and hoodies. The process involves transferring ink directly from a print head to the fabric using a heat press and a special paper known as DTF paper. This technique allows for vibrant, long-lasting prints that are both durable and soft to the touch.

The basic steps in DTF Cotton Printing include preparing the design digitally, printing it onto the DTF paper using a specialized printer, cutting out the design precisely, and then transferring it onto the fabric using heat and pressure. The use of cold peel DTF transfers ensures that the ink adheres firmly to the fabric without leaving any residue on the transfer paper. Custom DTF transfers are particularly favored for their ability to produce high-quality, personalized designs quickly and cost-effectively.

– Brief explanation of Direct to Fabric (DTF) cotton printing

Direct to Fabric (DTF) cotton printing is a cutting-edge technique that allows for precise and vibrant decoration on various fabric types, particularly cotton. This method bypasses traditional screen printing or heat transfer processes by directly applying inks to the fabric using specialized equipment. DTF for t-shirts has gained immense popularity due to its ability to produce high-quality, detailed designs with rich colors and a soft handfeel. It’s an ideal solution for custom t-shirt printing, enabling businesses and individuals to create unique garments quickly and efficiently.

When it comes to DTF transfers, precision is key. Misalignments or improper ink settings can result in print imperfections on the final product. To ensure optimal results with DTF printing for t-shirts, printers should pay close attention to registration, ink types, and drying processes. Avoiding common mistakes in this technique allows for the creation of stunning, long-lasting designs that meet customer expectations.

– Key components and materials involved

The process of DTF (Direct to Fabric) Cotton Printing involves several key components and materials that play a crucial role in achieving high-quality prints on garments. This method utilizes a unique technology where ink is directly applied to the fabric, skipping the need for traditional screen printing methods. The primary materials include custom sheets designed specifically for heat pressing designs onto various garments, DTF printing machines, and eco-friendly inks suitable for cotton fabrics. These custom sheets are pre-treated to ensure optimal ink absorption, allowing for vibrant and long-lasting prints.

Along with these essentials, proper preparation of the fabric itself is vital. This involves cleaning and priming the cotton material to create a smooth surface that facilitates even ink distribution. The DTF printing process also demands precise temperature control during the heat pressing stage, ensuring the ink fuses securely with the fabric fibers for durable results. When executed correctly, DTF printing for t-shirts and other garments offers a versatile and cost-effective approach to creating custom designs, making it a popular choice among fashion designers and small businesses alike.

In exploring the realm of DTF cotton printing, it’s clear that mastering this technique requires an understanding of its unique processes and common pitfalls. By avoiding mistakes such as improper material selection, inadequate preparation of fabric, and misalignment during printing, you can ensure high-quality, vibrant results. Remember, successful DTF printing involves a delicate balance between technology, skill, and attention to detail. Continue to experiment, learn from these insights, and let your creativity flourish through this dynamic medium.