Calculating DTF Cotton Printing costs involves balancing material, labor, and equipment expenses with overhead and market dynamics. Pricing strategies consider design complexity, fabric type, customization, turnaround time, and operational costs, requiring a flexible approach. Market research guides rates while ensuring profitability, factoring in specialized techniques and investments for high-quality printing services.

Unleash the potential of DTF cotton printing with a strategic pricing approach. This comprehensive guide navigates the intricate costs associated with this vibrant, bustling technique, helping you set competitive and profitable rates. From understanding fundamental expenses to factoring in market dynamics, we delve into the key elements shaping DTF cotton printing services. By the end, folks will be equipped to price their offerings effectively, ensuring both customer satisfaction and business success.

- Understanding DTF Cotton Printing Costs

- Factors Influencing Pricing Strategies

- Setting Competitive and Profitable Rates

Understanding DTF Cotton Printing Costs

Understanding DTF Cotton Printing Costs

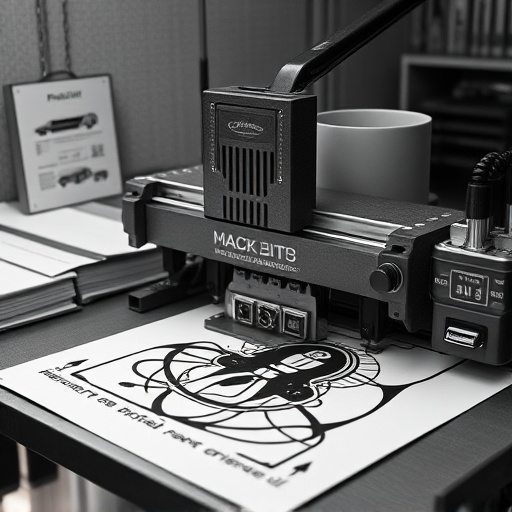

DTF cotton printing is a specialized process that involves transferring designs directly onto cotton fabric using heat and pressure. To price your services effectively, it’s crucial to have a clear grasp of the various costs involved. The primary expenses in DTF printing include materials, labor, and equipment. High-quality dtf heat transfer paper, advanced printing machines, and skilled technicians are essential for delivering exceptional results. Moreover, the cost of raw materials like cotton fabric varies based on factors such as quality, thickness, and type.

When pricing your dtf prints, consider not just the direct costs but also overhead expenses like utility bills, maintenance, and depreciation of equipment. Understanding these dynamics will help you set competitive prices while ensuring profitability. Remember that the market demand, urgency of projects, and custom nature of designs can also influence pricing strategies. As a result, flexible pricing models that cater to different client needs are often the best approach in this industry.

Factors Influencing Pricing Strategies

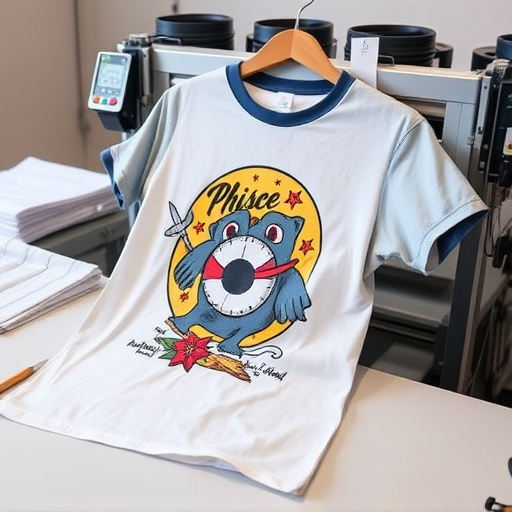

The pricing strategy for DTF (Direct to Fiber) cotton printing services is a nuanced art that considers several factors. One key element is the complexity and size of the design. Detailed, intricate patterns or large prints often require more time and resources, naturally translating to higher costs. The type of fabric also plays a significant role; different cotton varieties and thread counts can impact both durability and print quality, thus influencing prices.

Additionally, customization options such as special inks, finishes, or bulk DTF shirt production orders should be factored into the pricing model. Turnaround time is another critical aspect; urgent or rush orders usually come at a premium due to the tight scheduling involved. Moreover, overhead costs like equipment maintenance, facility rent, and labor rates can vary widely, affecting the overall price point of DTF transfer services and prints.

Setting Competitive and Profitable Rates

When setting rates for DTF Cotton Printing services, it’s crucial to strike a balance between competitiveness and profitability. Researching market rates is essential; understand what similar services charge to ensure your pricing aligns with industry standards while allowing for fair compensation. Remember that competitive doesn’t always mean cheapest—it means offering value that meets or exceeds customer expectations.

Consider the costs involved in DTF transfers, especially when printing on dark fabrics, as these can require specialized techniques and materials. A direct to film printer, a key component in DTF printing, demands significant investment and maintenance, so ensure your rates cover these expenses. Evaluate your operational costs, including labor, materials, and overhead, to set rates that are both profitable and attractive to clients seeking high-quality DTF cotton printing services.

In conclusion, pricing your DTF cotton printing services requires a delicate balance between understanding production costs, considering market demand, and setting competitive rates. By factoring in material expenses, labor, overhead, and profit margins, you can create a profitable pricing strategy that attracts clients seeking high-quality DTF cotton printing. Remember, staying informed about industry trends and offering flexible pricing options can help your business stand out in the market.