Prepare cotton fabric by cleaning, smoothing, and pre-treating for DTF Cotton Printing. Set up a dedicated print station with essential materials, mixing tools, and a clean workspace. Accurately prepare print paste according to manufacturer instructions. Apply designs using Direct-to-Fabric (DTF) techniques, ensuring even distribution and complete drying. Custom heat pressing sheets can enhance precision for bulk production or branded logos.

Discover the art of DTF (Direct-to-Fabric) cotton printing with this comprehensive guide. Learn how to transform plain cotton into stunning, durable designs step by step. From preparing your fabric for printing to applying and drying the design, each process is carefully detailed. Master the technique, explore creative possibilities, and unlock the potential of DTF cotton printing for unique, handcrafted textiles.

Prepare Cotton Fabric for Printing

Before initiating the DTF Cotton Printing process, it’s essential to prepare your cotton fabric for optimal results. Start by cleaning the fabric thoroughly to remove any dirt, oils, or contaminants that might interfere with ink adhesion. This step ensures a clean canvas for your custom graphic tees or personalized hoodies.

Next, ensure the fabric is smooth and free from wrinkles. Proper fabric preparation enhances the quality of the final print. Consider pre-treating the cotton with a suitable release agent to facilitate the easy removal of the cold peel dtf transfers after printing. This step streamlines the process and guarantees crisp, vibrant prints that truly bring your design to life.

Set Up and Mix Print Paste

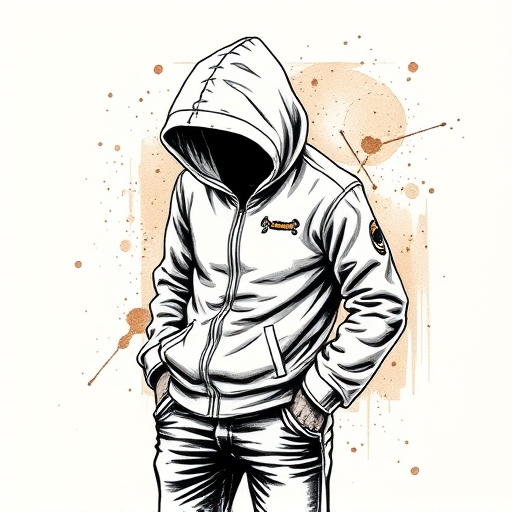

Setting up your print station is a crucial step in the DTF Cotton Printing process. Begin by gathering all necessary materials: your DTF (Direct to Fabric) printing machine, high-quality print paste suitable for cotton, a mixing palette or container, and tools like brushes, spatulas, and rolling pins. Ensure your workspace is clean and well-lit to facilitate precise mixing.

The print paste is the heart of your DTF transfer process. Mix the paste according to the manufacturer’s instructions, combining the base material with pigments to achieve the desired color. A consistent, smooth texture is essential for successful printing on cotton items like hoodies. Remember, the right paste composition ensures crisp, vibrant prints that will withstand wash cycles, making your DTF Cotton Printing experience truly remarkable.

Apply and Dry the Design

Once your design is finalized, it’s time to apply it to the cotton fabric using Direct-to-Fabric (DTF) printing. Start by ensuring your work area is clean and well-prepared. Spread a thin layer of DTF ink onto the fabric using a roller or brush, following the manufacturer’s instructions for the recommended amount. The key to a successful print lies in an even distribution of ink. Allow the ink to dry completely; this step is crucial as it ensures your design adheres properly during the heat pressing process. Custom sheets for heat pressing designs can be utilized at this stage to ensure precision and consistency, especially when dealing with bulk DTF shirt production or creating logos for clothing brands.

DTF (Direct to Fabric) cotton printing is a versatile and creative method that allows designers and artisans to bring their unique visions to life. By following these simple steps—from preparing the fabric to applying and drying the design—you can master the art of DTF cotton printing, enabling you to create stunning, durable textiles ready for various applications. Embrace this modern technique and unlock endless design possibilities with DTF Cotton Printing.